Maintenance Engineering for Operations and Fa

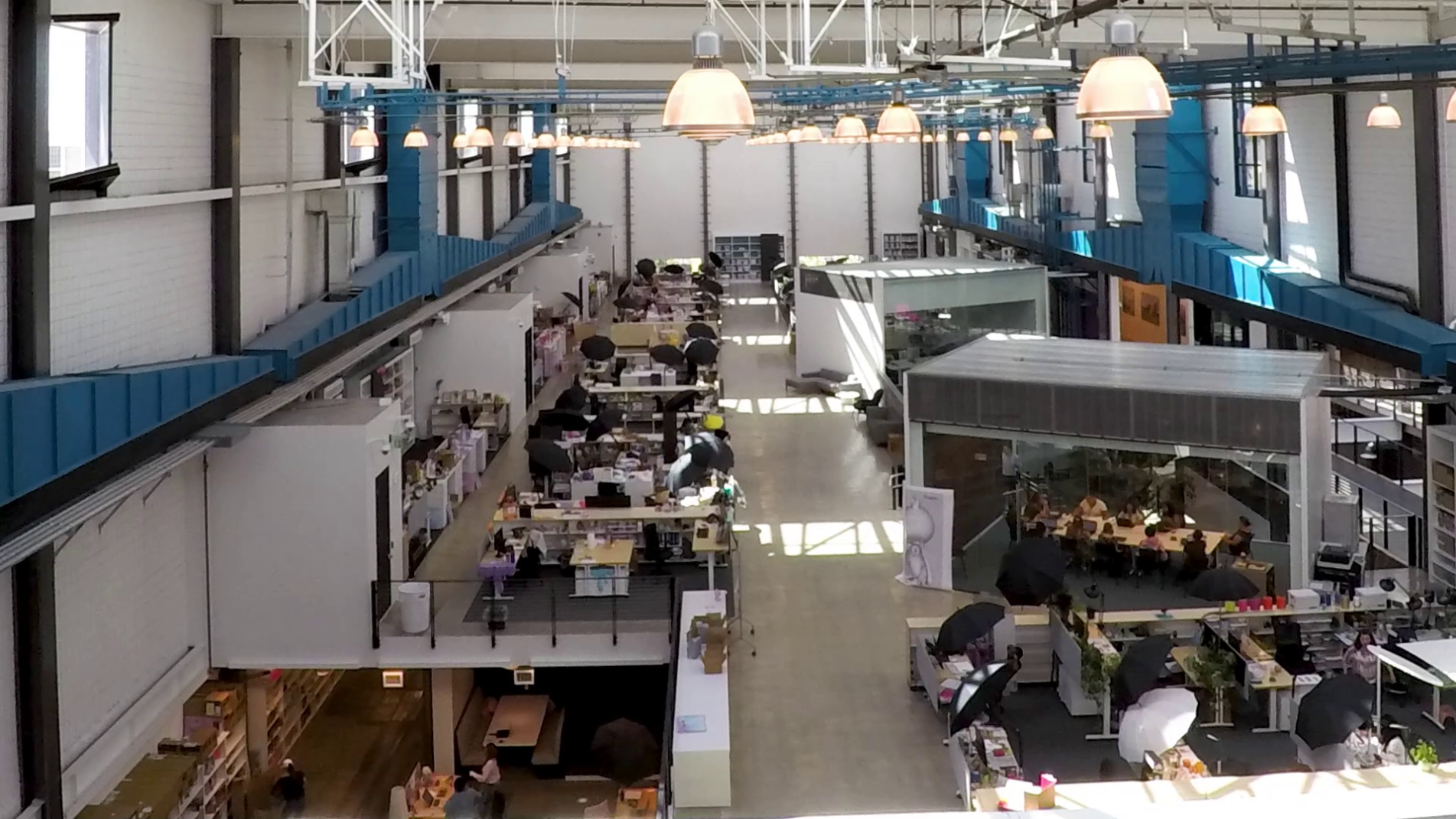

Mission: The Manager of Maintenance Engineering for Operations & Facilities will lead and manage the Maintenance Department for a large manufacturing facility, overseeing all functions related to the repair, maintenance, and optimization of manufacturing equipment and facilities. This role is crucial in ensuring operational efficiency, equipment reliability, and a safe working environment across HVAC, electrical systems, machine repair, and infrastructure maintenance, including plastics molding machinery, tow motors, and grounds.

Position Requirements

- •Bachelor’s degree in Engineering, Facilities Management, or a related field. Exceptional experience in lieu of formal education plus experience will be considered.

- 8+ years of experience in maintenance management, preferably in a manufacturing environment.

- Proven expertise in equipment repair, facilities management, and team leadership.

- Excellent knowledge of safety regulations, HVAC, electrical systems, and Lean Manufacturing principles.

- Strong problem-solving and communication skills, with the ability to manage complex, cross-functional projects.

- Must be able to work independently as well as part of a team.

- Intermediate level Microsoft Office Application Skills (Word, Power Point, Excel).

- Strong verbal and written skills are essential.

Authority

- Reports to VP of America’s

Key Result Areas and Activities

1. Leadership & Strategy

- Develop and implement a strategic maintenance plan to enhance equipment reliability, optimize resources, and minimize downtime.

- Lead a large team of skilled maintenance personnel, fostering a high-performance culture focused on accountability, efficiency, and continuous improvement.

2. Equipment & Machinery Maintenance

- Oversee maintenance, repair, and troubleshooting of complex equipment, including blow molding, injection molding, and rotational molding machinery.

- Manage preventive and predictive maintenance programs for plastics molding machinery, HVAC systems, and other critical equipment.

- Ensure timely and effective repair of tow motors, forklifts, and other facility vehicles to minimize operational interruptions.

3. Facilities Maintenance & Infrastructure

- Oversee facilities maintenance, including HVAC, electrical systems, and plumbing to ensure regulatory compliance and safe operations.

- Supervise grounds maintenance, including roof and asphalt patching, to maintain a safe and visually appealing environment.

- Collaborate with safety and operations teams to uphold a safe, compliant, and well-maintained work environment

4. Process Improvement & Efficiency

- Implement Lean and Six Sigma principles to streamline maintenance processes, reduce costs, and improve asset longevity.

- Regularly review and analyze maintenance data to identify trends, prevent recurring issues, and recommend cost-effective solutions.

5. Budgeting & Cost Control

- Develop and manage the Maintenance Department budget, tracking expenses, and ensuring cost efficiency in repair and maintenance activities.

- Evaluate and approve purchase requests for tools, supplies, and replacement parts, ensuring cost-effective procurement. Generate and obtain Spend documents when necessary. Coordinate with the Procurement Dept. where necessary.